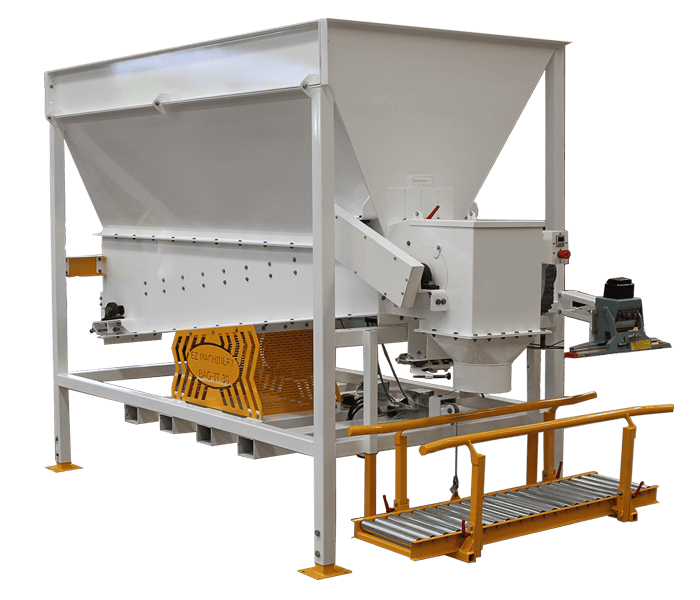

Bagging Machines & Sand Baggers: Semi automatic bagging equipment

Our sandbaggers and semi-automated bagging machines are built tough and designed to handle a vast range of products across a wide range of industries, such as agriculture, landscaping, food and earthmoving.

Whether you’re bagging manure, cattle feed or working with other materials like sand, gravel, grains and soil, speed and efficiency is the focus.

The EZ Machinery Bag-It range makes short work of bagging and allows you to spend more time on other tasks. See our product range below and if your product isn’t there please fill in a form because we offer custom solutions and may be able to help.

Features of EZ Bagging Machines

Product Enquiry

"*" indicates required fields

Benefits of Using a Bagging Machine

Bagging Plant FAQ’s

Can the bags be filled to a desired weight?

Yes, the simple touch screen control panel enables the operator to set the desired weight required.

What type of bags can be used?

All types of bags can be used, including plastic, paper, Poly woven and Hessian. In addition to different bag types, there are also a range of bag sizes that can be used.

Can open mouth bags be used with automated bagging machines?

Automated bagging machines are designed to work with specific types of bags, including open mouthed bags. For open mouth bags specifically, there are automated systems designed to handle these types of bags. If you’re unsure which of our systems is best for your product, our friendly team is here to help. Just give us a call.

What type of material can be processed?

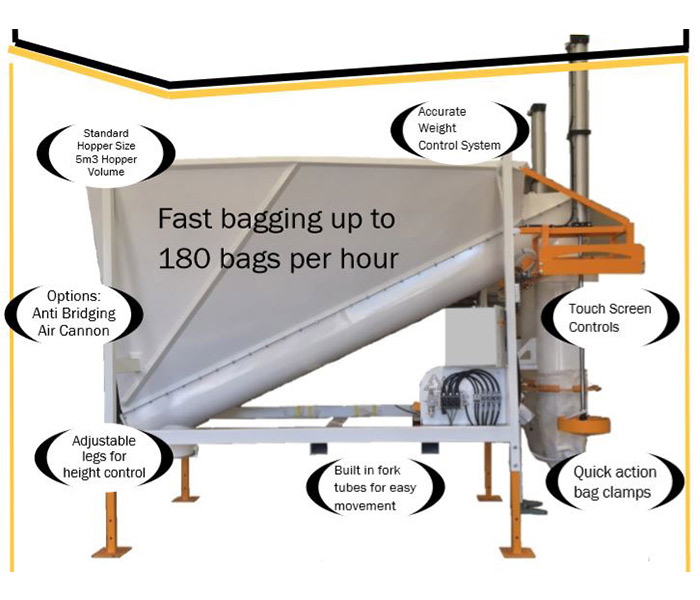

EZ Machinery produces a number of product specific bagging plants. However, The Bag-it 30 for example, is an automatic bagging setup that is capable of – sand, soil, bark, compost, stock feed, crushed glass, grain, nuts, pebbles and much more.

How many bags per hour can be produced with automated bagging?

Depending on the method of bagging selected (volume or weight) bagging rates between 200 and 240 bags per hour (based on 20KG bags). Some bagging methods can produce and fill more bags at a faster speed than others.

How many cubic metres can the hoppers hold?

Depending on the model of Bagging Plant, the Bag-it 30 will hold 3m3 while the bag-it 15 can hold 1.5m/3.

Can the Bagging Plants be supplied with a screw conveyor?

Yes, all models of bagging plants can be supplied with a screw conveyor.

What power is required to run the units?

Depending on the model, most units are 240V 15 Amp single phase. Some models are 415V while a select few are petrol or diesel-powered hydraulically driven.

What are the internal dimensions of the Bag-it 30 hopper section?

1.6m W x 2.9m L x 2.5m H.

What is the weight of the Bag-it 30?

1400KG.

What power is required to run the units?

Depending on the model, most units are 240V 15 Amp single phase. Some models are 415V while a select few are petrol or diesel-powered hydraulically driven.

Can the bagging plants be moved around?

Bagging Machines for Different Materials

Sand Bagging Machines

Gravel Bagging Machines

Grain Bagging Machines

Soil Bagging Machines

Other Materials

Bagging Machines for sale Australia

Product enquiry

Product Enquiry

"*" indicates required fields